Plastic Cups Screen Printing

Plastic cups are an inexpensive and effective method for your clients to promote your company during a function or conference. Plastic cups are ecologically beneficial since they can be recycled and are cost-effective when ordering in bulk. They are mainly used for drink. At festivals, industry events, and big gatherings, provide your visitors with a new method to promote their company. Customized designing plastic cups permit huge numbers for painting, providing your clients with the stock they require to promote their product. These cups are the more popular party item. Create an event memorable for your customers by branding it.

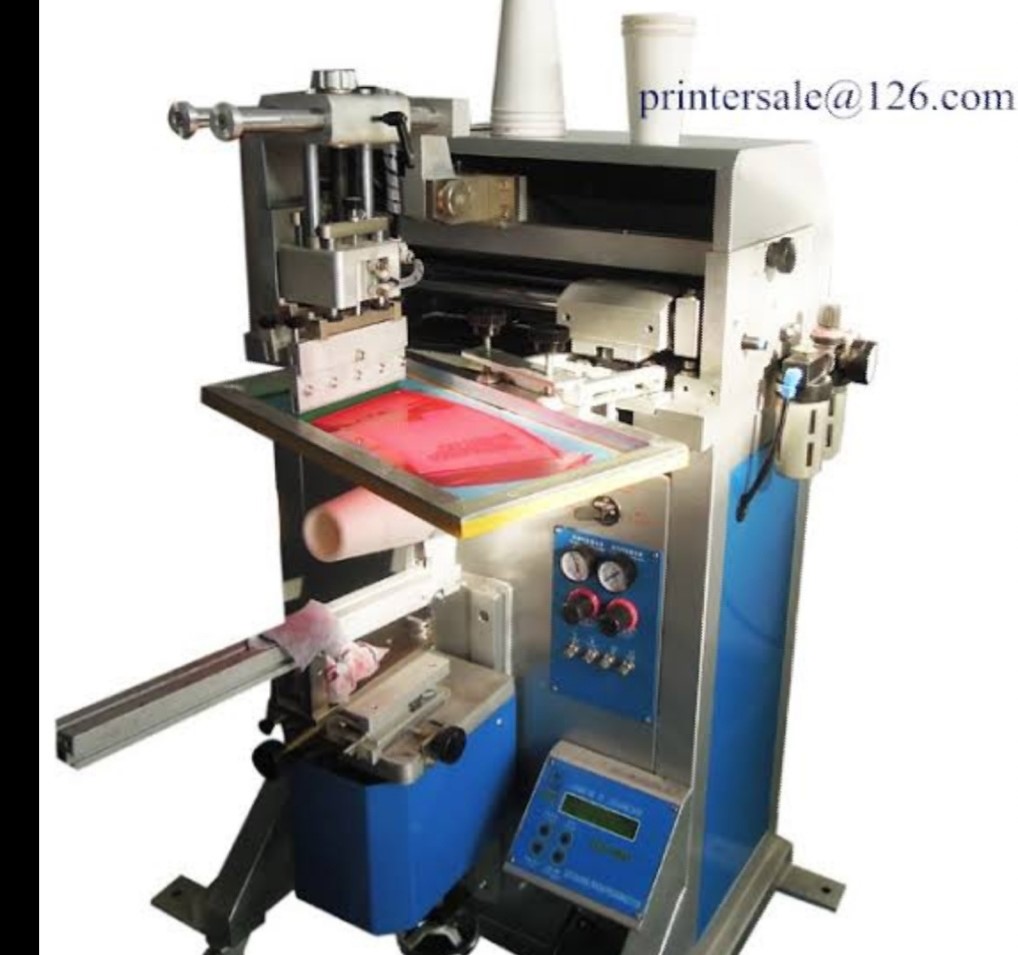

Our screen-printing equipment is ideal for assisting your business in quickly filling contracts. At https://autoprintmachine.com Systematic Machinery can meet your design requirements while also providing your clients with manufacturing quality printing.

Why Should You Use Systematic Automation For Your Cups?

Systematic Automation provides polymer products screen painting machines to new and existing printing companies to update their equipment. We provide a variety of bespoke equipment made in the United States.

The T8-SS is a market requirement for automated manufacturing stamping on polymer mugs. Can change out mandrels connected to the display for various shaped paper cups. An automatic sealing system is incorporated into the device. We utilize our Super Light SV technology; however, when you want to be LED, we can use Phoseon. The material is packed as well as arranged for shipping after it has been made and dried. The T8-SS is designed for the user, even for individuals who have no prior panel designing expertise.

The Model F1-DC is a flexible and user-friendly machine that has been named “the most dependable display painting machine ever produced.” This device is ideal for beginners and expert printers, thanks to its quick and precise painting and object changeover time of less than a minute. Plastic cups manufacturing is easy and inexpensive. Changing the mandrels on your manufacturing apparatus takes a few seconds and couldn’t be simpler. For many color identification, mechanically and visual devices are employed.

Both methods provide flexible machining for various cup sizes and other items altogether. You may use one of the two devices to design your complete cup inventory.

Printing in Various Colours Using Industry-Leading Quality and Management

The ONCE-TECH is your answer if you want to evaluate the design of many colors on your mugs. Based on the kind of cup and the method of identification, mechanical properties verification is possible. Usually, polymer cups may be manufactured with a slot on the base to allow for registrations of multi-color printing. Laser enrolment is used to classify a product based on its color. When you don’t possess any registered spots, we are apply a tiny sticky to the base of your goods throughout the printed procedure to allow for multicolored registration. Possibilities for automating your production, like automated preprocessing, rapid reloading, and much more, are available in the ONCE-TECH. Our experts will collaborate with you to develop a solution that is appropriate for your purpose.