How To Get The Latest PCB Prototype Services For Our Electronic NPI

The field of technology is constantly developing when the latest appliances and technology are invented daily. Getting such items through the launchpad to reach the market is known as New Item Release. When you haven’t, already you’ll be continuing via a similar production cycle shortly, beginning using a PCB prototype. Below is the information regarding electrical development, which will ensure the achievement of your upcoming device launch.

Each big firm uses prototyping, as well as manufactured PCB board creation is no different. A robust model may open the road only for the foundation’s development process. After done, your devices would be prepared for marketplace introduction. However, in constructing a great prototype, you will have to work with a PCB maker specializing in the finest PCB technology demonstrator services.

Your PCB Prototype: The Beginning Of The Release Of Your Latest Item

Marketing the latest products is a lengthy procedure that usually begins with such a working PCB model and ends with the unique item idea becoming available for manufacturing.

Presentation of a Unique Device Through Concept with Verified Technology

The procedure of developing a concept into a marketable device is called Product Innovation Opening and NPI. Its design may consume a significant amount of effort and money in need to guarantee that now the manufacturing model edition of any device could be created at the most excellent standards of effectiveness while suffering the fewest industrial expenses. UETPCBA gives much preparation is typically put into the NPI of such a unique circuit device to meet these objectives, beginning from the PCB design.

The Importance of a PCB Prototype

A production version is frequently utilized to represent both the original design and final project management, although there is a significant difference. Prototyping seems to be the outcome, including its early phases of designing, during which experts experiment with several ways to develop their thing. Each stage of the construction phase is highly exploratory, and several variants of an idea can be generated to identify the optimum condition to meet the model parameters.

When the sample meets the basic parameters, it may modify this layer before complete manufacturing. Such a brand creation phase of a project aims to optimize the functional prototype to output. Updates affecting usability, device efficiency as well as lifetime would be performed below. Moreover, item creation depends on the first models, and the result of the model is critical to the team’s achievement.

Engineering Design Expertise

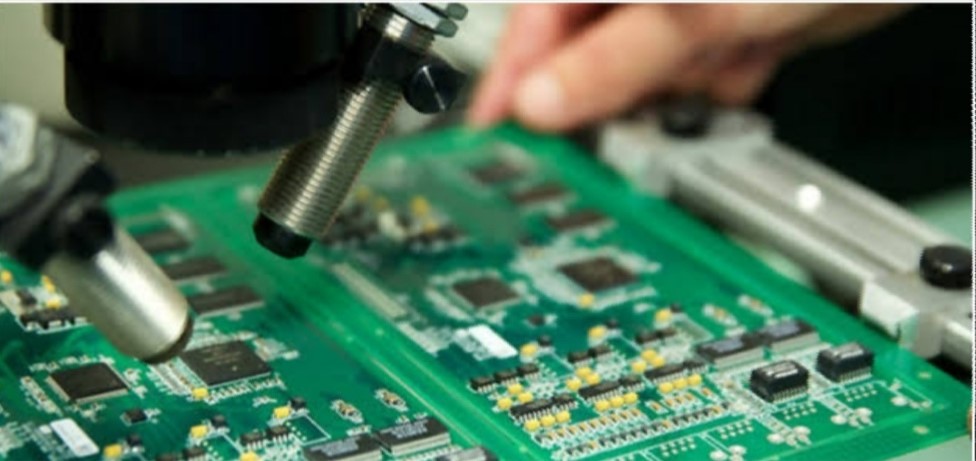

Turnkey PCB assembly sometimes need technical work on the side of such parts suppliers. The PCB CM would evaluate the items on functionality, accessibility, and pricing via a test of such panel elements. I am following as the CM will undertake an architecture and three best (DFM) analysis and provide relevant DFM or circuit functionality and efficiency suggestions discovered through the study. In certain circumstances, the CM may be required to propose corrective measures derived from their assessment findings and create unique design elements needed to address the prototype’s short deadline.